A car, a medical device, and a communication tool are usually assembled from multiple components, which generally need to be connected through various methods such as screw connection, rivet connection, buckle connection, adhesive connection, etc. Most of the assembly is mainly screw connection.

As is well known, screws come in different sizes, specifications, and functions. In addition to ensuring the connection quality of the entire product, it is also necessary to consider the user's safety and experience, ensuring reliable functionality without affecting the appearance. This involves the key process technology in the assembly process - tightening process. Rigorous tightening process design and intelligent tightening tools need to ensure high precision of tightening, stable and controllable tightening process, and qualified tightening data.

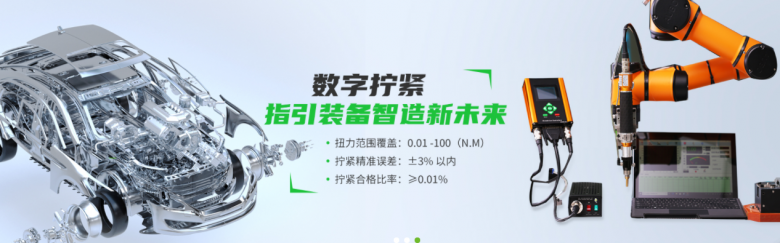

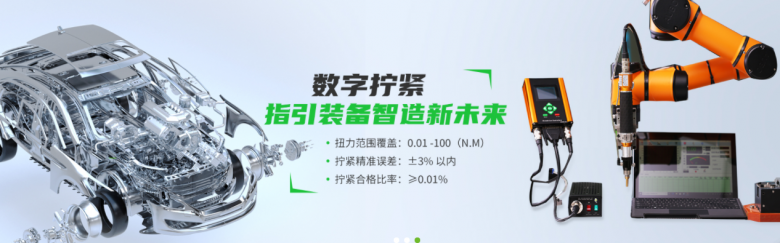

In the process of product assembly, various types of tightening tools are usually used, as the accuracy of different tools directly affects the stability of the assembled screws. Therefore, suitable tightening tools are usually selected according to assembly requirements. And the quick digital tightening provides a safe and reliable choice for major manufacturing enterprises, allowing lean manufacturing to truly land.

After years of deep cultivation in the field of fastening, we have been the first to master the core algorithm of digital tightening, and have constructively proposed the concepts of "intelligent tightening" and "digital tightening" in the industry. Adhering to the service concept of pursuing innovation, we continue to innovate and research and develop tightening tools, providing our customers with industry-leading tightening tools and continuously creating higher market value and benefits.

With the rapid development of electric fastening tools and the continuous improvement of product lines, the strategic layout effect of quick action products has been significant, attracting the attention of many domestic and foreign customers. With professional technology, high-quality products, and comprehensive services, we have formed a good reputation among the population pursuing higher quality of use, gradually becoming a strong brand of industrial grade fastening tools.

Brushless servo electric screwdriver, rooted in the fastening industry for many years, thanks to the new brushless motor control technology, can provide the most stable output during operation. Within the performance parameter range, it can freely set and adjust torque, rotation speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening. Even when facing complex work environments, one can easily handle them. In addition, for tightening points involving safety and functionality, the tightening curve and result of each screw will be synchronously stored in the controller, greatly improving product quality and optimizing the tightening process to ensure the tightening quality delivered to users. Relying on the core algorithm of digital tightening, the quick acting brushless servo electric screwdriver can work more logically and intelligently to meet the needs of the manufacturing industry. From process design, tightening guidance, to technical standards and process control, the quick action also reflects rigor and meticulousness.

In the future, while continuously promoting the development of digital tightening technology, Speed Digital Tightening will actively explore and innovate, promote high quality with high standards, give back to society with a new attitude, continue to carry forward the spirit of innovation, promote the high-quality development of the new infrastructure industry, and make greater contributions to "Made in China".