What kind of electronic devices will be presented in the future? I believe everyone has their own opinions, but among these opinions, more people believe that "smart wearable devices" will be the mainstream of the future. What is an intelligent wearable device? Intelligent wearable devices refer to the general term for devices that use wearable technology to intelligently design and develop wearable devices for daily wear, such as electronic watches, wristbands, glasses, clothing, etc.

In the past, people's understanding of watches was mostly limited to electronic watches and quartz watches. However, after Apple released the smartwatch, the watch industry ushered in a new upheaval, sparking a trend of smart manufacturing. People are beginning to feel the tremendous changes that technological innovation has brought to their lives, and are more willing to accept intelligent and humanized products. In the future, it is foreseeable that smartwatches will become a mainstream choice for wearing.

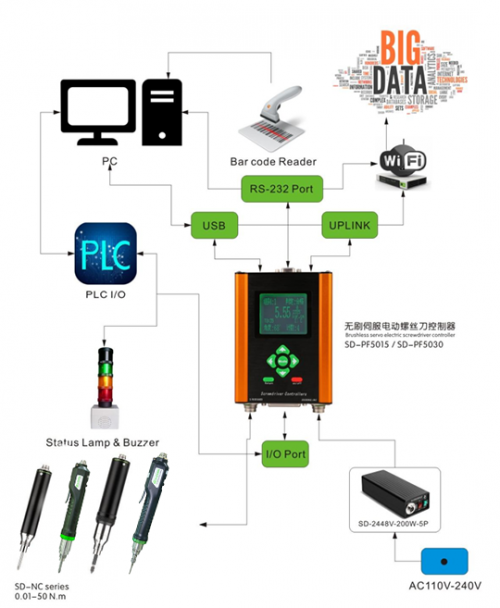

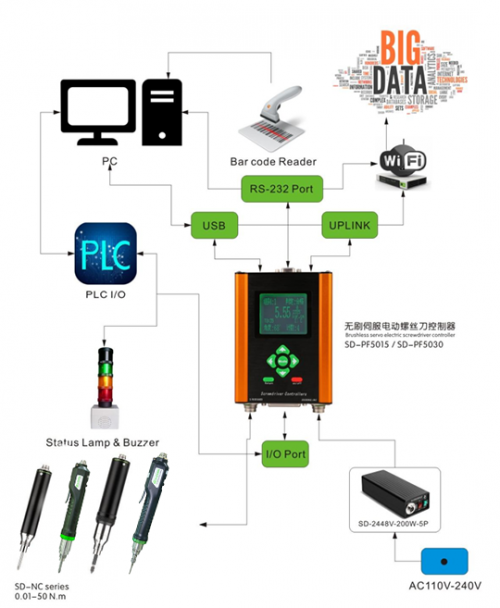

The implementation of excellent concepts also requires corresponding high-tech to be transformed into reality. Smart watches not only have high requirements for chips and software, but also pose new requirements for their installation process. At present, the electronic manufacturing industry has extremely strict requirements for product assembly efficiency and quality. For tightening assembly processes, with the iteration and upgrading of product assembly processes and the improvement of quality requirements, it is necessary to simultaneously improve the performance and function of tightening tools. This requires the tightening system to have rich data interfaces, comprehensive traceability functions, and ultra-high tightening accuracy, and the clock industry is no exception.

Previously, the assembly of watches was mostly done manually, but small screws and the fragility of hardware have resulted in a low yield rate in watch production. But in the wave of intelligent manufacturing, it can be foreseen that in the future, watches will only become smaller and thinner. Faced with this market demand, there is an urgent need for the support of digital tightening technology.

The main reason why the screws on a smartwatch are difficult to tighten is because they are small. The quick action brushless intelligent electric screwdriver has accumulated 21 years of tightening product development technology, with high precision, high efficiency, torque accuracy deviation of 3%, and can reduce tightening costs by 70%, with an error rate of less than 6 parts per million. Its patented technology has mastered the core algorithm and meets various tightening conditions.

At the same time, the electronic hardware in smartwatches is relatively fragile, and if scientific tightening methods are not used during tightening, it is likely to break. The quick action brushless intelligent electric screwdriver can achieve free programming of the tightening assembly process. Within the performance parameter range, it can tighten completely according to the set tightening plan, freely set and adjust the torque, speed, waiting time, and rotation direction, achieving precise tightening. Each screw can be tightened in multiple steps, supporting up to 5 steps.

In addition, the quick acting brushless intelligent electric screwdriver records all important tightening process parameters in real time through built-in torque sensors and angle sensors. The data collection system on its computer can provide a more intuitive view of the entire tightening process, while also storing tightening data and calculating the work qualification rate, improving data traceability.

Technology drives the future. In today's fierce market environment and competitive ecosystem, precision electronic manufacturing industries such as the watch industry are facing enormous challenges and pressures. The assembly process is developing towards precision, automation, and intelligent driving, and the requirements for automation, intelligence, standardization, and traceability of tightening operations and tightening data are also increasing. The fast acting electric screwdriver empowers the watch industry with new technology for production, While improving productivity, it also significantly increases product yield, helping to achieve a win-win situation of cost and efficiency.