In recent years, with the development of the economy and technological progress, automation has become a major trend in modern industrial development, especially for the tightening process that occupies an important position in the factory assembly process. Due to the demand for precision, automation, and intelligence in the assembly process, there is an increasing demand for automation, intelligence, standardization, and traceability of tightening data in tightening operations. As a result, automated tightening technology has been vigorously developed, and automated tightening tools have sprung up like mushrooms after rain.

As a leading player in the industry, Quick Acting Intelligent Tightening has a high sensitivity to changes in the times and is a promising tool for industry development with its own scientific research capabilities. With more than a decade of deep cultivation in the industry, QuickAction has continuously explored and researched in the tightening industry, and has constructively proposed the concepts of "digital tightening" and "intelligent tightening" in the industry. This not only breaks the long-term monopoly of foreign brands, but also empowers tightening tools with more possibilities for intelligence and automation, creating a "domestic brand" that is trusted by millions of users.

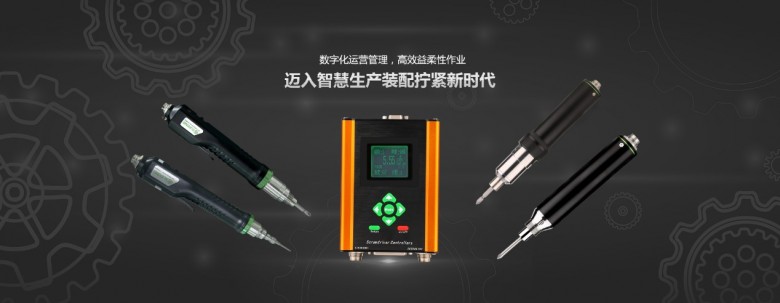

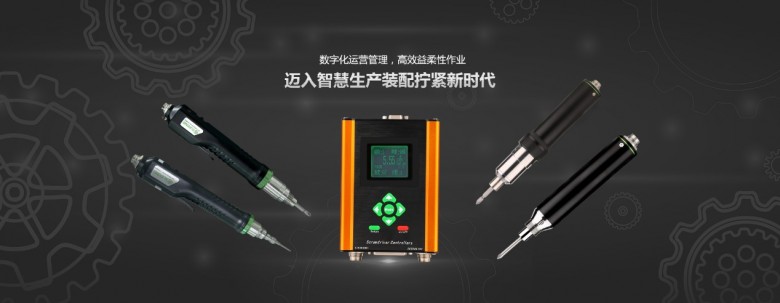

Faced with the diversified requirements of the times, Speed Intelligent Tightening adheres to the business philosophy of "tightening is the core of all scientific research and technology", and provides intelligent tightening products and services to customers. Its brushless intelligent electric screwdriver, with its unique advantages of leading technology, excellent performance, high cost-effectiveness, data traceability, and automation, has sold over 1 million units globally, exported to more than 200 countries and regions worldwide, providing the most adaptable digital tightening assembly services for millions of users.

The industry-leading precision tightening enables the precise development of quick action leading tightening tools. The quick acting SUDONG brushless intelligent electric screwdriver accurately controls the torque accuracy of millions of tightening assemblies within a standard deviation of ≤ 3%. Within the performance parameter range, it is possible to freely set and adjust torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening.

The technology leading data traceability function enables the digital development of quick action leading tightening tools. Through the built-in current and angle sensors, precise control of the brushless servo electric screwdriver during various tightening processes can be achieved, and all important tightening process parameters can be recorded in real-time. The data acquisition system on its computer side makes the entire tightening process more intuitive, while also storing tightening data and calculating work qualification rates, improving data traceability.

The leading advantage of cost reduction and efficiency improvement enables the efficient development of quick action leading tightening tools. The intelligent tightening system optimizes the tightening process, improves production efficiency, reduces rework caused by common tightening faults such as floating locks, sliding teeth, and diagonal strikes, and reduces unnecessary production costs. The intelligent tightening system comes with various tightening error warnings, combined with efficient tightening schemes, which not only improves productivity but also significantly increases product yield.

In the future, Speed Drive will continue to make efforts, continuously research and innovate tightening technologies, continuously master core technologies, and continuously optimize tightening tools. We will continue to create maximum benefits and higher market value for our customers with a complete range of categories and one-stop high-quality services.