Due to its advantages of standardized components, simple assembly, convenient disassembly, high efficiency, and low cost, bolted connections are widely used as the most basic, standardized, and widely used connection method in the factory assembly process. In the era of increasing global demand for intelligence and automation, the automation, intelligence, and digitization of tightening processes are increasingly valued by various industries and enterprises. This requires companies to always be prepared for transformation, upgrading, and product innovation.

As a leading supplier of intelligent tightening tools and automated tightening solutions in the industry, Quick Action Intelligent Tightening always keeps pace with the changing times, fully leverages its leading technological advantages, continuously optimizes and upgrades its products, and provides high-quality products and services to customers in industries such as automobiles, electronics, home appliances, medical, and aviation, fully promoting the precision and intelligence of intelligent manufacturing and tightening assembly in China.

Precise fastening and high precision

The quick acting SUDONG brushless intelligent electric screwdriver accurately controls the torque accuracy of millions of tightening assemblies within a standard deviation of ≤ 3%, which is second to none in the industry. Within the performance parameter range, it can freely set and adjust the torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening. It is one of the important links to improve the precision of the entire assembly process.

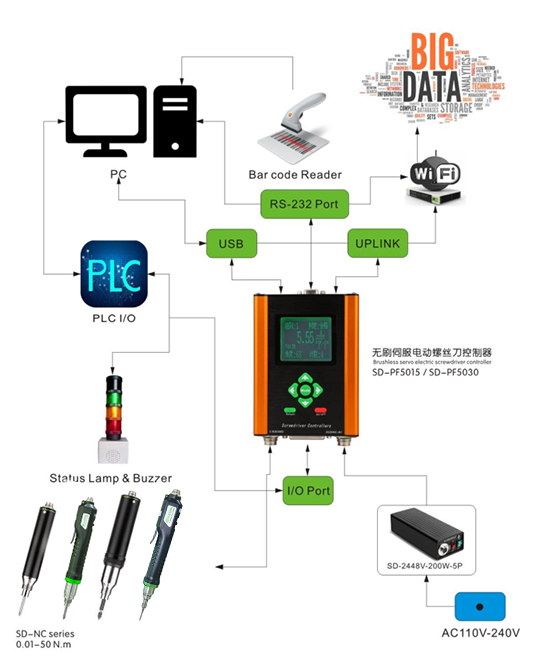

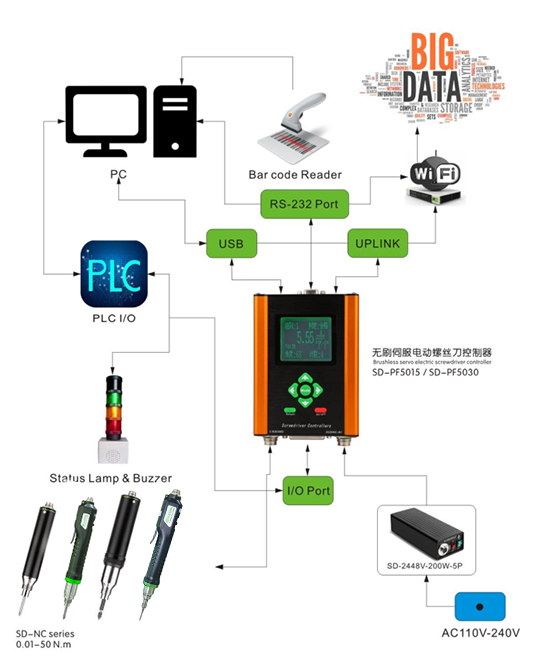

Data traceability and comprehensive digitization

Through the built-in current and angle sensors, precise control of the brushless servo electric screwdriver during various tightening processes can be achieved, and all important tightening process parameters can be recorded in real-time. The data acquisition system on its computer side makes the entire tightening process more intuitive, while also storing tightening data and calculating work qualification rates, improving data traceability. The importance of digitization is reflected in every aspect of Intelligent Factory 4.0, and the tightening assembly process that allows for data traceability is the trend of future factory development.

Quality assurance and efficiency

The intelligent tightening system with quick action will continuously optimize the tightening process, improve production efficiency, reduce rework caused by common tightening faults such as floating locks, sliding teeth, and diagonal strikes, and reduce unnecessary production costs. The intelligent tightening system comes with various tightening error warnings, combined with efficient tightening schemes, which not only improves productivity but also significantly increases product yield. Production cost and efficiency are of utmost importance in the production process. Quick action intelligent tightening empowers production with technology, helping to achieve a win-win situation between cost and efficiency.

Faced with the diverse demands of Industry 4.0 and Made in China 2025, Quick Action Intelligent Tightening not only proposes new concepts of "digital tightening" and "intelligent tightening" to assist in factory automation and assembly precision, but also promotes the rapid development of China's intelligent tightening field by comprehensively showcasing leading industrial tightening technologies and products, enhancing advanced brand positioning and influence.