The sudden outbreak of the COVID-19 epidemic has caused a serious shortage of medical equipment. For related medical equipment enterprises, increasing production in a short period of time can easily lead to product problems such as poor assembly quality and increased scrap rates. In order to ensure the quality of each batch of medical equipment, it is required that every step in the manufacturing process of medical equipment be precise, data-driven, and traceable. As the most common way of assembling medical equipment parts, bolt connection is particularly important for tracing and monitoring the tightening process.

Why is bolted connection so important for the assembly process of medical equipment?

Compared to welding, bonding, riveting and other processes, bolted connections have the characteristics of being detachable, highly controlled, and reliable. In the assembly of medical equipment, tightening is used in multiple places and is a very important step. Any tightening error at any point may affect the later use of the entire equipment. Correspondingly, if some bolts are not tightened correctly and complete data is not recorded and stored, it will not only affect the use of the equipment, but also consume a lot of time and energy in the later accident investigation. Therefore, the importance of intelligent bolt connection process is self-evident.

How to achieve digitalization of the tightening process for quick action intelligent tightening?

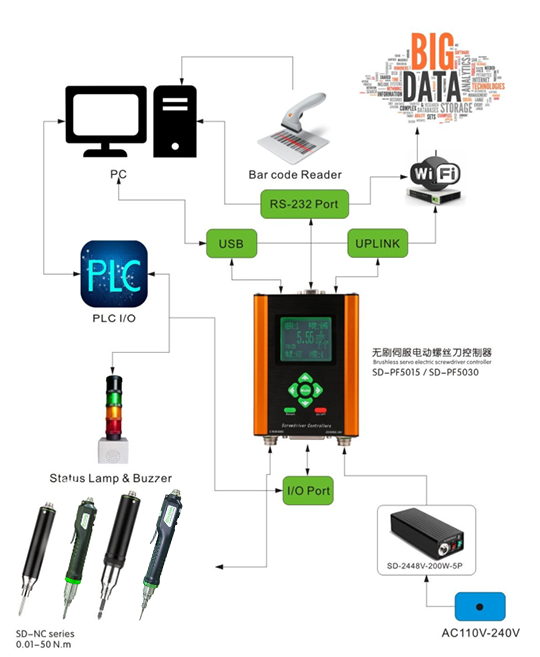

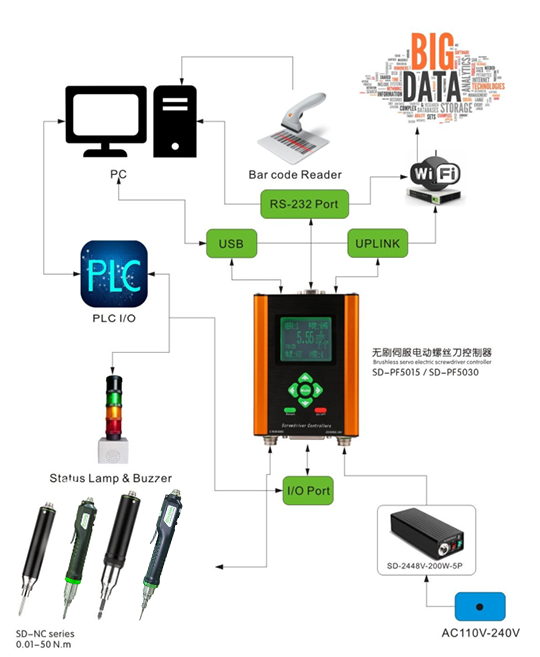

As a leading enterprise in the electric tool industry, Sudong was awarded the title of Guangdong Province High tech Enterprise in December 2017. With years of professional digital tightening experience, it has provided professional, intelligent, and traceable digital tightening services to numerous customers in the medical industry. Quick Action understands the accuracy of the tightening process and the importance of data traceability in the assembly process of medical equipment. On the one hand, its computer-based data collection system stores tightening data and calculates work qualification rates, improving data traceability. On the other hand, it can also provide flexible and diverse tightening schemes, and can connect various error prevention accessories to reduce tightening failures, shorten downtime, and improve normal operating time. The digital tightening process provides safe, reliable, and traceable bolt connections for the overall assembly process of medical equipment.

How to achieve precision in the tightening process with quick and intelligent tightening?

The quick acting SUDONG intelligent brushless electric screwdriver is based on servo control technology, which can ensure that the torque accuracy of millions of tightening assemblies is controlled within a standard deviation of ≤ 3%. And it can freely set multiple tightening parameters according to different tightening process requirements, achieving precise tightening. The use of brushless servo motors significantly reduces operating costs, prolongs lifespan, and ensures robust power performance and peak torque output, making it an ideal choice for CNC tightening assembly processes. In addition, the intelligent tightening system comes with various tightening error warnings, combined with efficient tightening schemes, which not only improves productivity but also significantly increases product yield. Faced with the rapidly increasing demand for medical equipment, the precision of the tightening process has to some extent accelerated the assembly process and improved productivity.

Under the epidemic, the quality of medical equipment needs to be more guaranteed. When the quality is related to life safety, traceability during the assembly process becomes particularly important. As a leader in the tightening industry, Quick Action's intelligent tightening technology provides "protection" for the entire assembly process of medical equipment. With technology as a "weapon", it participated in this battle "epidemic" and well assumed the social responsibility of enterprises in special times.