Industrial tightening technology is one of the most common and important assembly processes in industrial manufacturing. Electric screwdrivers are often used to tighten and loosen screws, mainly for assembly lines, and are one of the essential tools for most production enterprises. Regarding the tightening of screws, the most widely used ones on the market are still ordinary electric screwdrivers and pneumatic electric screwdrivers. However, with the development of the economy and the advancement of technology, China's industrial manufacturing industry is gradually transforming, and products are constantly being updated. The original ordinary electric batch and pneumatic electric batch gradually cannot meet the development of digital industrial manufacturing in the Industry 4.0 era.

Why do tightening tools require intelligent upgrades?

Bolt connection is one of the most widely used methods in industrial manufacturing. Sometimes, hundreds of components of a machine are fastened with bolts. In mass production, assembly workers have to assemble dozens or hundreds of machines every day, and the number of these bolts is quite astonishing. Traditional manual or pneumatic tightening tools cannot guarantee uniform torque for each bolt, seriously affecting the assembly quality and efficiency of the product. Currently, the market has increasingly high requirements for product quality and reliability, which requires improving assembly quality.

As a leading supplier of intelligent tightening tools and automated tightening solutions in China, QuickAction Intelligent Tightening Technology (Guangdong) Co., Ltd. is committed to helping customers from all walks of life solve tightening problems such as low production efficiency, high error rates, low product assembly quality, and high repair costs in industrial production tightening processes, and helping partners achieve digitalization and intelligence in the tightening process.

How to break through the situation and achieve digitalization of electric screwdrivers with quick and intelligent tightening?

The electric batch industry belongs to a high-tech industry, but due to the low research and development level of most enterprises in the industry, technical difficulties cannot be overcome. Based on this, as a leader in the industry, QuickAction has the courage to shoulder corresponding corporate responsibilities, starting from the most important technological research and development, and continuously carrying out independent innovation and product upgrades. Not only has QuickAction broken down technological barriers, but it has also mastered core tightening technologies, ensuring its leading position in the tightening industry.

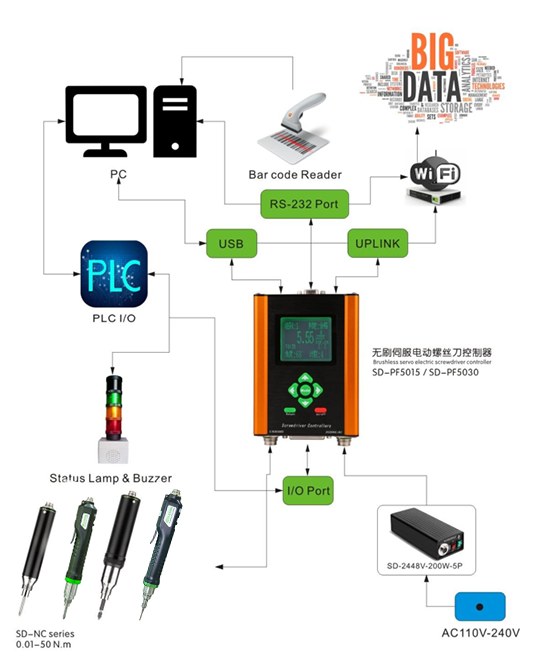

Technology is the primary productive force. Compared to previous assembly methods, the intelligent torque display electric screwdriver independently developed by Quick Action has obvious advantages in intelligent tightening: firstly, it can reduce the labor intensity of workers, improve work efficiency, and reduce bolt tightening time by one-third; The second is to monitor, prompt, and alarm the entire homework process, achieving a 100% pass rate of bolt tightening torque and a 0% bolt leakage rate; The third is to control the operation process and achieve standardization of process operations; The fourth is the advanced data traceability function that meets the needs of customer data recording and torque detection, truly achieving intelligent assembly.

In the assembly process of industrial manufacturing, every tightening of a screw is a conversation with the machine. As an indispensable intelligent tightening tool in the assembly process, the quick intelligent torque display electric screwdriver real-time process control and status display, massive data storage and quality traceability functions, provide high-precision, high reliability, high durability, and highly intelligent tightening tools and services for users in various industries!