The 2020 Shanghai Munich Electronics Exhibition, known as the benchmark of China's electronics industry, has successfully concluded at the Shanghai National Convention and Exhibition Center with the theme of integrating innovation and guiding the future with intelligence. The three-day (7.3-7.5) exhibition attracted electronic industry professionals from all over the country to come and admire the future development trends of the electronic industry.

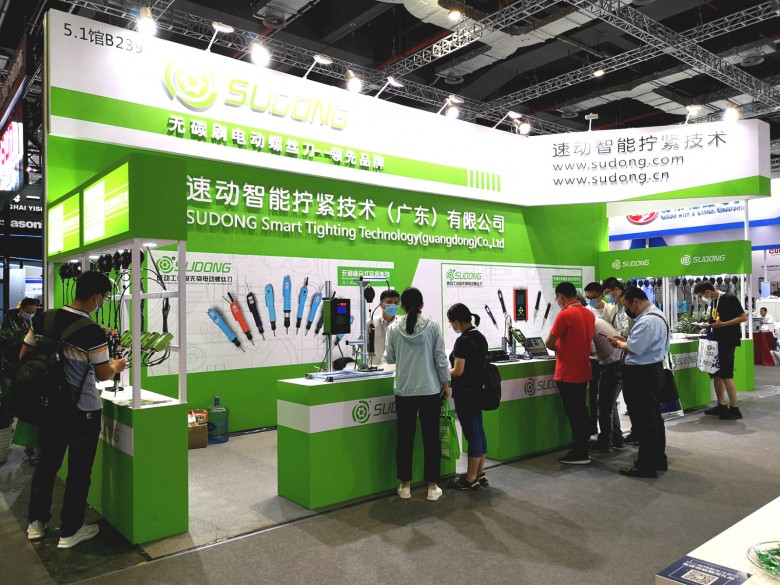

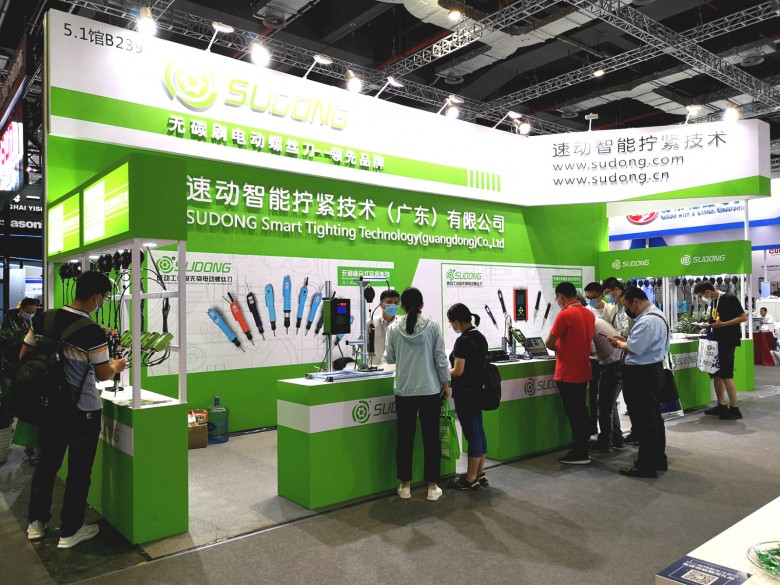

Nearly 3000 exhibiting companies and over 100000 industry elites and professionals participated in this exhibition, covering the entire electronic manufacturing industry chain. QuickAction showcases its leading intelligent tightening technology, intelligent tightening tools, and solutions at booth 5.1B-239, engaging in diverse and multi-dimensional communication and interaction with customers, and witnessing this large-scale "electronic feast" with global electronics industry leaders.

It is reported that this grand event mainly revolves around keywords such as "5G", "new infrastructure", and "artificial intelligence", with a focus on showcasing advanced technologies such as semiconductors, sensors, embedded systems, testing and measurement, and equipment manufacturing. Quick action intelligent tightening brings the latest carbon free brush intelligent electric screwdriver torque tester and surrounding supporting products, showcasing the cutting-edge intelligent tightening technology and breakthrough technological achievements in the industry to exhibitors and enterprises, covering multiple fields such as automotive, industrial electronics, medical, aerospace, etc., to help "Made in China 2025".

The three-day exhibition, featuring a booth with a sense of on-site technology, a professional technical team, and innovative cutting-edge technology products, has become a beautiful scenery in the exhibition. It has not only received high attention from many industry insiders, but also attracted visitors to stop and exchange ideas, as well as merchants from all over the industry to negotiate at the booth. The outstanding and leading products have also won unanimous praise from the professionals present.

At this exhibition, Quick Action Intelligent Tightening showcased the unique advantages and shining highlights of its carbon free brush intelligent electric screws and intelligent tightening technology to all exhibitors.

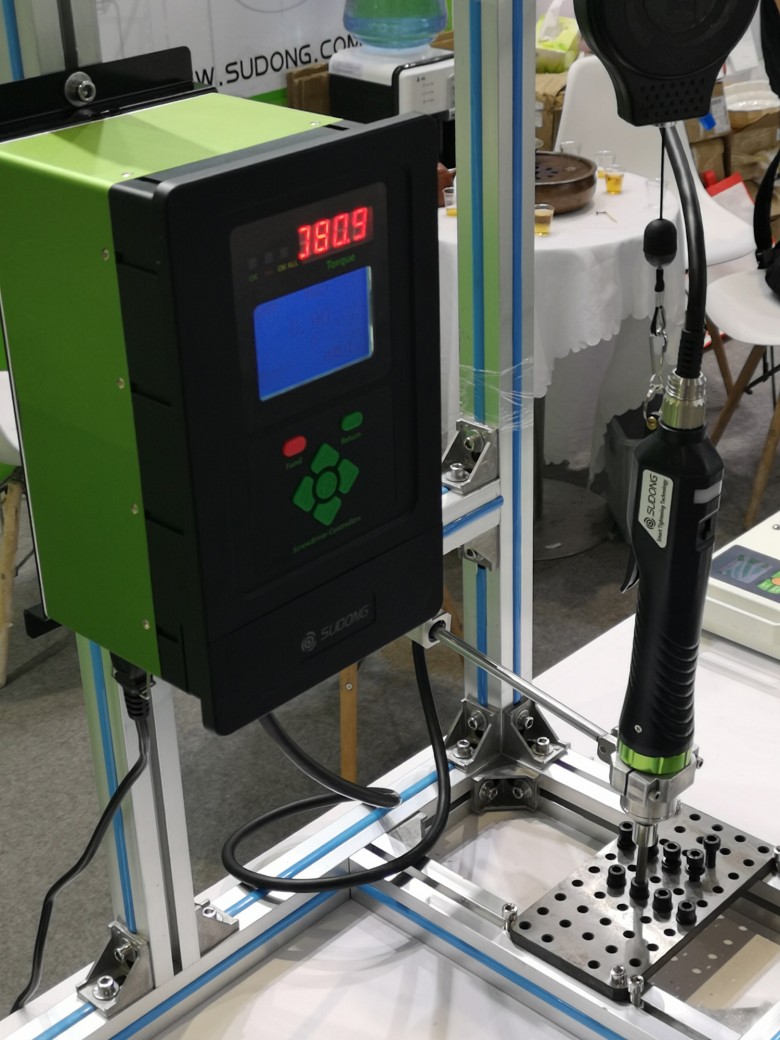

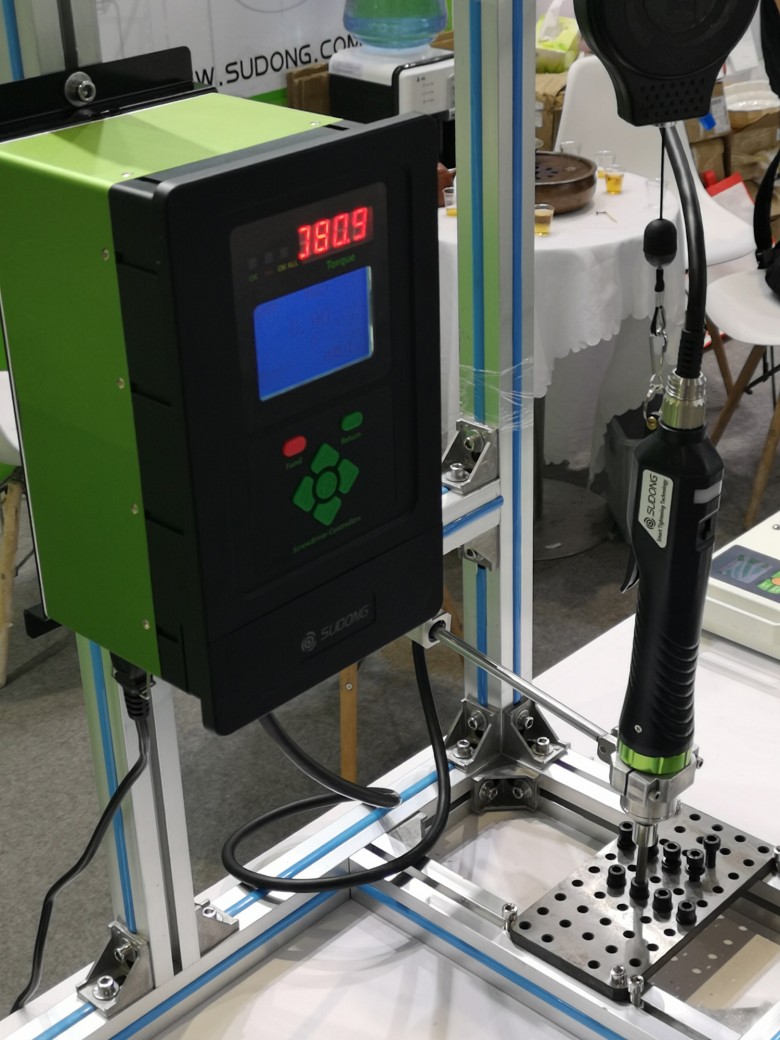

Highlight 1: Leading fastening accuracy. The quick acting SUDONG brushless intelligent electric screwdriver accurately controls the torque accuracy of millions of tightening assemblies within a standard deviation of ≤ 3%, which is second to none in the industry. Within the performance parameter range, it can freely set and adjust the torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening. It is an essential tightening tool in the assembly process of intelligent factories.

Highlight 2: Unique data traceability technology. Through the built-in current and angle sensors, precise control of the brushless servo electric screwdriver during various tightening processes can be achieved, and all important tightening process parameters can be recorded in real-time. The data acquisition system on its computer side makes the entire tightening process more intuitive, while also storing tightening data and calculating work qualification rates, improving data traceability. The importance of digitization is reflected in every aspect of Intelligent Factory 4.0, and the tightening assembly process that allows for data traceability is the trend of future factory development.

Highlight three: Comprehensive cost reduction and efficiency enhancement advantages. The intelligent tightening system with quick action will continuously optimize the tightening process, improve production efficiency, reduce rework caused by common tightening faults such as floating locks, sliding teeth, and diagonal strikes, and reduce unnecessary production costs. The intelligent tightening system comes with various tightening error warnings, combined with efficient tightening schemes, which not only improves productivity but also significantly increases product yield. Production cost and efficiency are of utmost importance in the production process. Quick action intelligent tightening empowers production with technology, helping to achieve a win-win situation between cost and efficiency.

Looking back in recent years, the electronics industry has been undergoing rapid transformation and innovation. The continuous maturity and collision of technologies such as 5G, AI, and the Internet of Things have accelerated the development process of the entire industry. At this critical moment of intelligent manufacturing transformation, this Muzhan is an opportunity, a challenge, a gain, and a growth for Speedo. As a practitioner and pioneer of high-quality development, Sudo will bravely lead the trend in the future, uphold the development concept of research and development innovation, constantly break through difficult boundaries, and strive to enhance the core competitiveness of intelligent tightening tools. We will explore more innovative possibilities for intelligent tightening under the background of "China's intelligent manufacturing", and provide new innovation and growth points for the development of China's electronics industry!